From Drawings to Digital Twins: How Modern Prefab Engineering is Rewriting the Rules of Construction

In the traditional world of construction, “measure twice, cut once” was the gold standard. But in the high-stakes era of modern infrastructure, even that isn’t enough. The industry is shifting from the dusty clipboards of the past to a future defined by Digital Twins and high-precision Prefab Engineering.

At Enclave Technology, we aren’t just drafting plans; we are building the digital nervous system of your next project. Whether you’re a developer looking to slash timelines or an architect aiming for impossible geometries, understanding the leap from “drawings” to “digital twins” is the key to unlocking true efficiency.

What is Prefab Engineering? (More Than Just “Off-Site”)

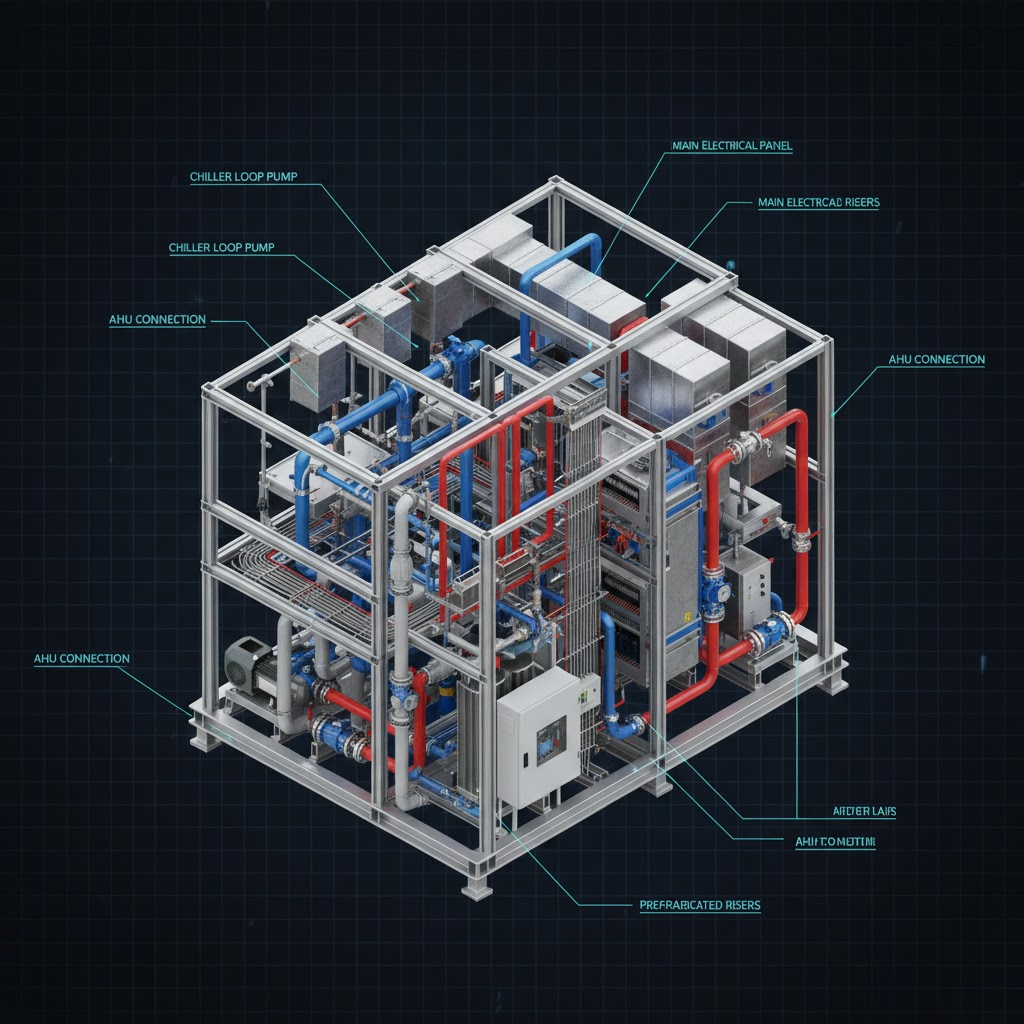

To the uninitiated, “prefab” might evoke images of temporary modular trailers. However, modern prefab engineering is a sophisticated discipline where components—from MEP (Mechanical, Electrical, and Plumbing) systems to structural steel frames—are engineered, fabricated, and tested in a controlled factory environment before they ever touch the job site.

The Evolution: From Paper to Pixels

For decades, construction relied on static 2D drawings. These were open to interpretation, leading to “clashes” on-site where a pipe might hit a beam that wasn’t accounted for.

Enclave Technology utilizes Digital Twin technology. A Digital Twin is a living, breathing virtual replica of your physical asset. It doesn’t just show where a wall goes; it simulates how that wall interacts with thermal loads, structural stress, and utility lines.

Alt Text: Enclave Technology’s digital twin model showing detailed MEP prefab engineering modules

Why Choose Enclave Technology for Prefab Engineering?

Furthermore, the “Enclave Way” is built on a foundation of precision and partnership. We don’t just act as a vendor; instead, we act as an extension of your design team.

First and foremost, we focus on the elimination of on-site surprises. By resolving every bolt and weld in a virtual environment, we effectively eliminate the dreaded “field fixes” that bleed budgets dry. In other words, if it works in our Digital Twin, it will work on your site. Additionally, we prioritize radical sustainability. Because construction waste is a global crisis, prefab engineering allows for “nesting” materials. Consequently, we can calculate the exact amount of steel or timber needed with near-zero waste. Finally, this leads to accelerated timelines. While the site is being excavated, we are already fabricating the building; as a result, project schedules are often reduced by 30-50%.

Our Specialized Service Areas

At Enclave Technology, we provide a holistic suite of engineering and design solutions tailored for the prefab industry.

MEP Prefabrication Modeling

We specialize in modularizing complex mechanical and electrical systems. Instead of 20 different contractors tripping over each other in a tight corridor, we design a single “skid” or “rack” that arrives on-site ready to be plugged in.

Structural Steel & Facade Engineering

From intricate curtain walls to heavy industrial frames, our engineering team ensures that every component is optimized for weight, strength, and ease of transport.

BIM (Building Information Modeling) Management

We don’t just use BIM; we master it. We provide Level 400 and 500 LOD (Level of Development) models that serve as the “source of truth” for the entire project lifecycle.

How We Work: The Enclave Roadmap

Transparency is the heartbeat of a successful project. Therefore, we follow a structured roadmap to take your vision from a concept to a physical reality.

Phase 1: The Discovery & Audit We start by understanding your goals. Specifically, we look at site constraints and budget requirements. We review your initial architectural sketches in order to identify opportunities for modularization.

Phase 2: The Digital Twin Creation Next, our engineers develop a high-fidelity 3D model. We use advanced software to run simulations, thereby checking for structural integrity and system clashes before production begins.

Phase 3: Design for Manufacturing and Assembly (DfMA) Following this, we move into the DfMA stage. We don’t just design for “function”; rather, we design for “assembly.” We ensure every piece can be shipped on a standard truck; similarly, we verify it can be lifted by the specific crane available on your site.

Real Voices: What Our Partners Say

“Enclave Technology transformed how we approach our healthcare projects. Their ability to turn complex MEP layouts into install-ready prefab modules saved us three months on our last hospital build. Their team feels like a natural extension of our own.”

— Marcus T., Senior Project Manager

“The level of detail in Enclave’s Digital Twins is staggering. We saw exactly how the facade would handle wind loads before we even broke ground. It’s a level of confidence I haven’t found elsewhere.”

— Sarah L., Lead Architect

FAQ: Everything You Need to Know About Prefab Engineering

Q1.Is prefab engineering more expensive than traditional methods?

Initially, the design phase may seem more intensive. However, when you factor in the reduction in labor costs, the elimination of waste, and the massive time savings, the Total Cost of Ownership (TCO) is significantly lower.

Q2.Can prefab designs be “creative,” or are they all boxes?

This is a common myth! Thanks to Digital Twin technology, we can engineer complex curves and unique geometries. Prefab is about how it’s built, not what it looks like.

Q3.At what stage should I involve Enclave Technology?

The earlier, the better. To get the most benefit from DfMA (Design for Manufacturing and Assembly), we recommend involving our engineers during the schematic design phase.

Q4.How do you handle “Digital Twin” updates?

Our models are dynamic. If a change is made on-site, it is reflected in the twin, ensuring that your “as-built” documentation is actually accurate for future maintenance.

Ready to Build Smarter?

The bridge between a great idea and a great building is Engineering. At Enclave Technology, we provide the technical expertise to ensure your project is built faster, greener, and with surgical precision.

Let’s turn your 2D drawings into a high-performance Digital Twin